10 4172 2169 0022 1000382 page 2 of 7 5 4 0 271 9 1058 11 thickness working condition effects friction and the impacts of tool geometry on spring back formation to bending processes were.

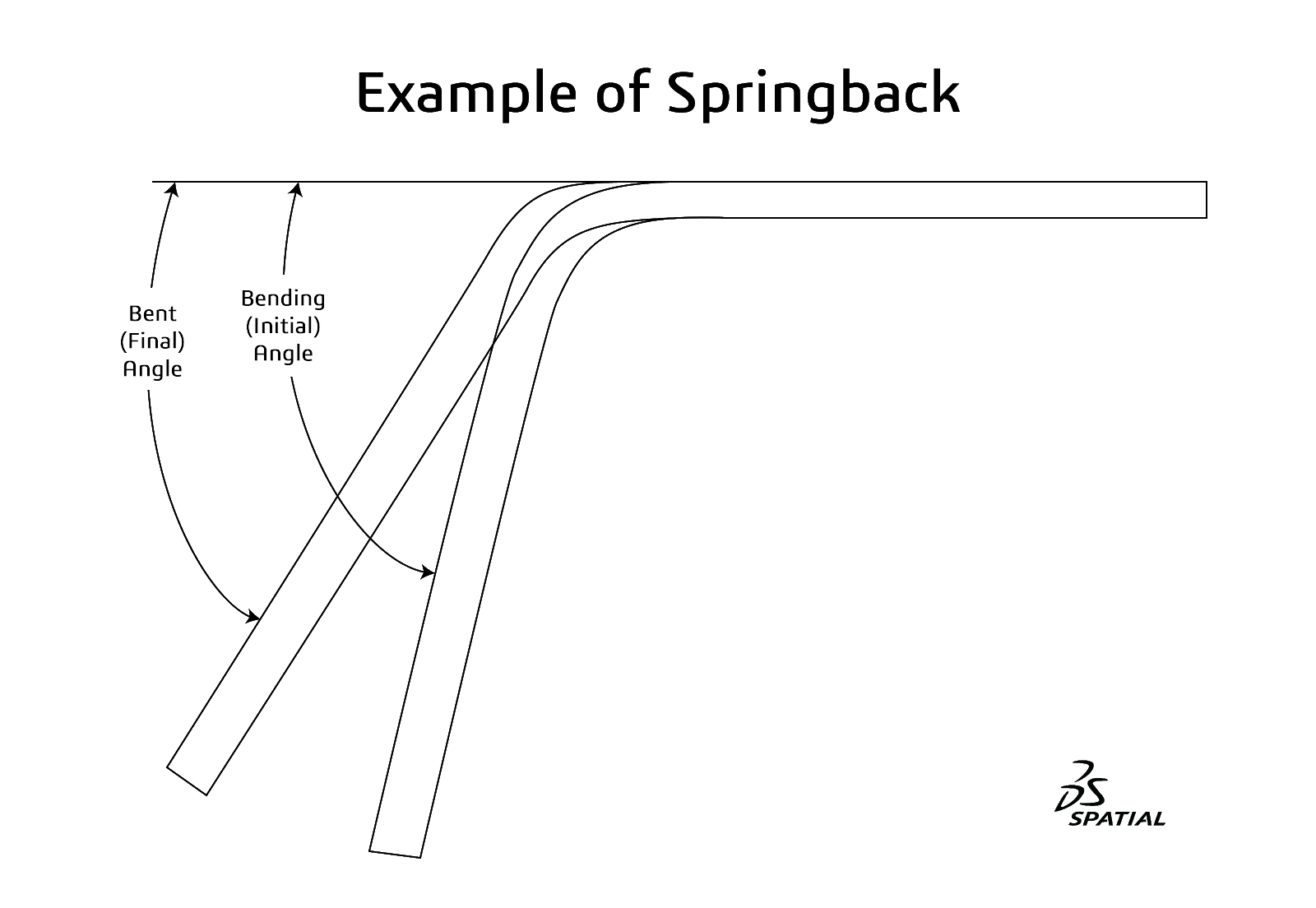

Spring back effect in sheet metal bending.

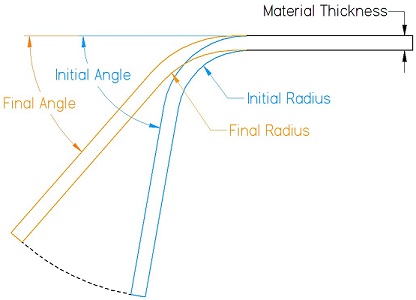

1 the final bend angle after spring back is smaller and the final bend radius is larger than before.

Calculate and mitigating the springback effect in sheet metal.

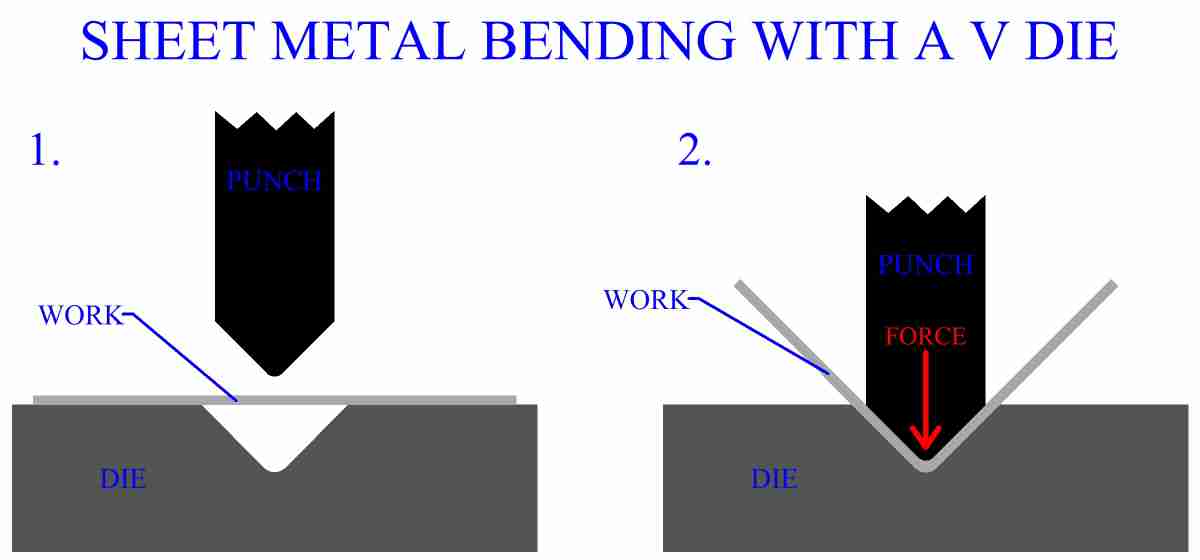

When a metal forming tool is planned and designed to deform a work piece the shape imparted by the tool will be a combination of elastic and plastic deformation.

The correcting bending force can elongate the inner and outer fiber in the deformation zone and achieve the forming effect.

There are two basic views as to why spring back occurs one states that it is due to the displacement of molecules and the other considers spring back in terms of a stress strain diagram.

Due to this elastic recovery it is necessary to over bend the sheet a precise amount to acheive the desired bend radius and bend angle.

This phenomenon can easily be observed by bending a piece of wire or a short strip metal.

In this work sheet metal thickness and depth of forming effect on spring back is analyzed using finite element methods.

Spring back occurs not sheets or plate but also in bending bars rod and wire of any cross section.

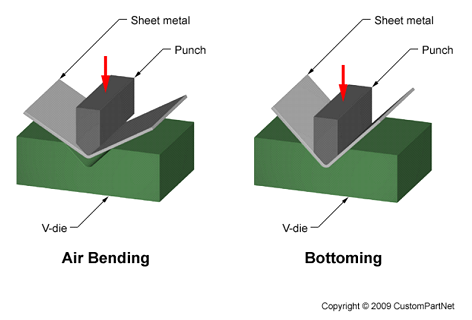

Figure 3 coining bottom bending and air forming affect stressstrain properties differently.

The spring back has to be compensated to achieve an accurate result.

Therefore if the bending force is the same in both ways the final effect will be different.

In bottoming and coining bending methods that usually produce 90 degree bend angles the line curves to the right of the vertical axis showing how the metal springs forward to conform to the die angle.

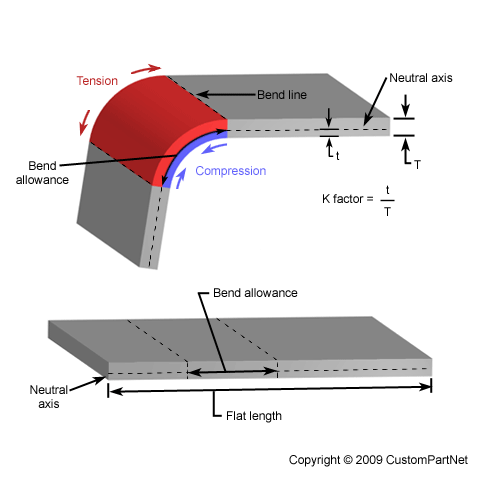

The final bend radius and bend angle can be approximated from the sheet thickness k factor material yield.

Springback is the geometric change made to a part at the end of the forming process when the part has been released from the forces of the forming tool.

The greater the correction force required to correct bending the smaller the springback of stamping parts.

Akinlabi 7 stated about the bending operation and springback based geometrical inaccuracies of bent parts.

When the bending.

This type of springback problem is easily adjusted for by adding simple over bend or compensation.

As shown in fig.

J material sci eng 6.

The release of the elastic deformation is the spring back often observed at the end of a metal forming process.

Spring back occurs when a metal is bent and then tries to return to its original shape.

Upon completion of sheet metal forming deep drawn and stretch drawn parts spring back and thereby affect the dimensional accuracy of a finished part.

The curved line in the air forming zone shows how springback changes at different bend angles.