Steel sheet pile is classified in two construction applications permanent and temporary.

Steel sheet pile waler details.

Steel sheet piles are most commonly used in deep excavations although reinforced concrete sheet piles have also being used successfully.

Historically such shapes have been hot rolled products of structural mills.

Maintains one of the largest rental inventories of domestically produced hot rolled steel sheet piling products in the united states as well as a full complement of h piling sections combi wall system combination wall piling and peiner beams.

Interlocking piles should be specified to prevent water ingress where significant groundwater is anticipated.

The full sheet pile wall is formed by connecting the joints of adjacent sheet pile sections in sequential installation.

The ability of a sheet pile section to perform is dependent upon its geometry and the soils it is driven into.

Steel sheet pile is a rolled steel section consisting of a plate called the web with integral interlocks on each edge.

Steel piles can be driven into the foundation without extensive excavation.

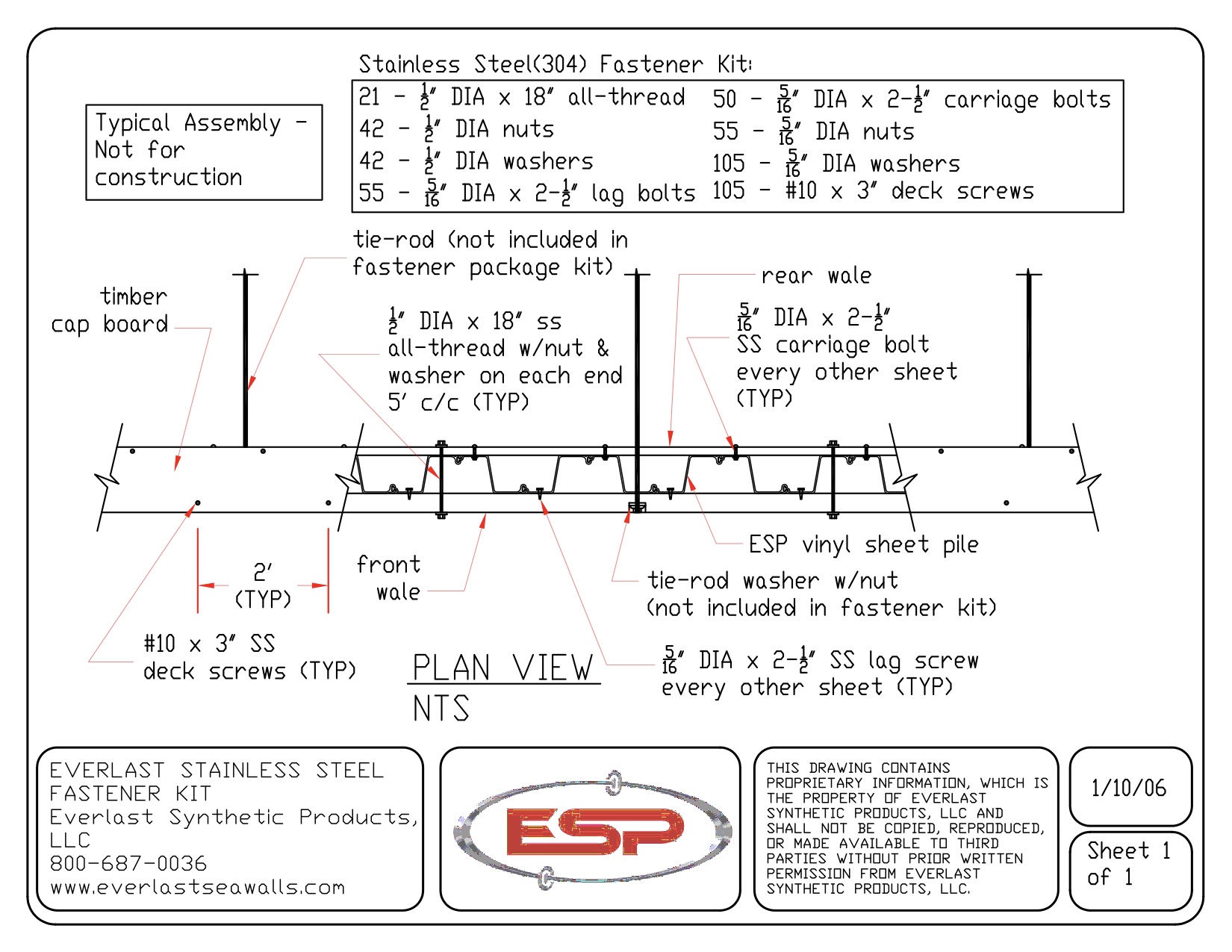

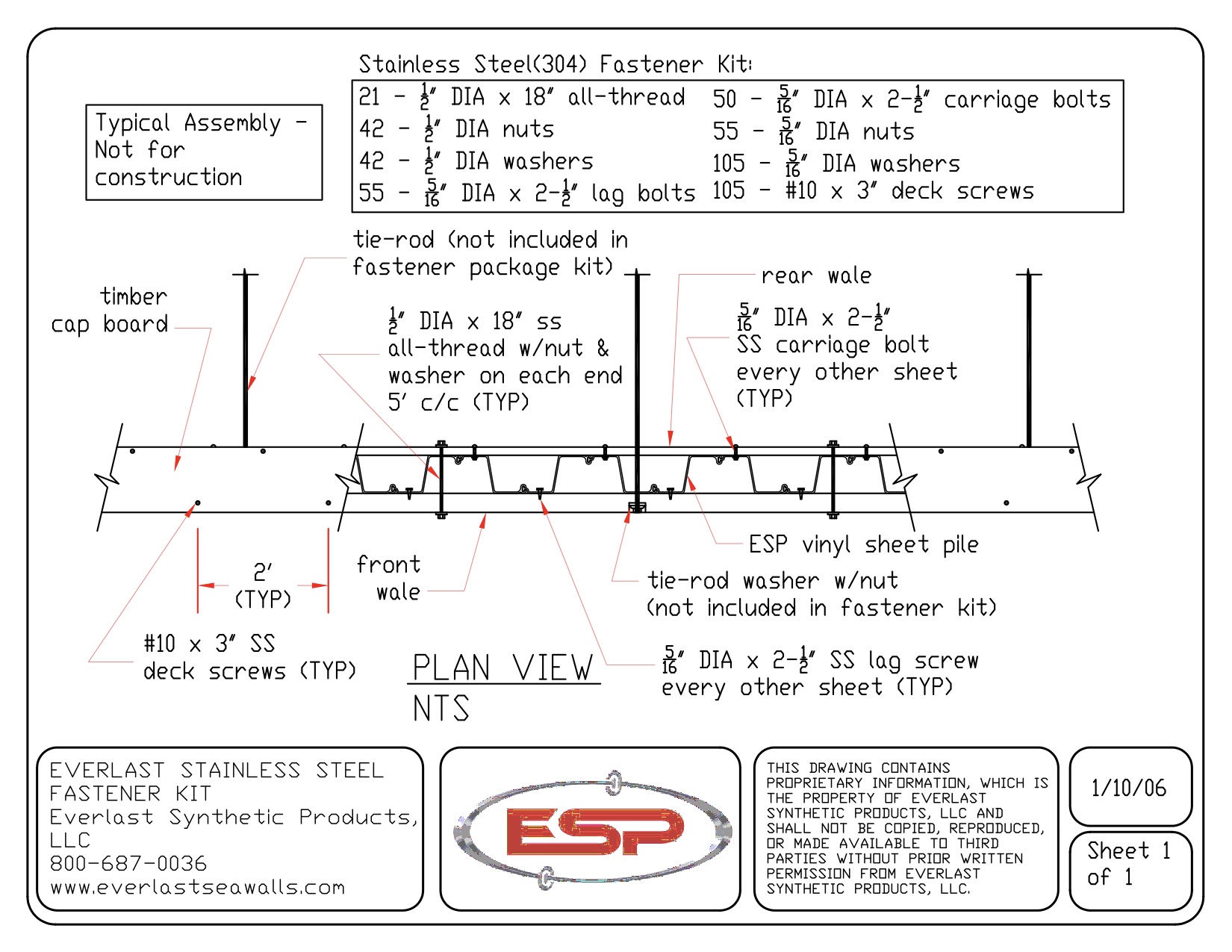

Steel sheet piling design manual notice the information including technical and engineering data figures tables designs drawings details suggested procedures and suggested specifications presented in this publication are for general information only.

A permanent application is stay in place where the sheet piling wall is driven and remains in the ground.

The ability of a sheet pile section to perform is dependent upon its geometry and the soils it is driven into.

Steel sheet piling is manufactured in three basic configurations z u and straight flat.

Sheet piles are one of the most common types of earth retention structures.

Like other shapes such as beams or channels they are formed during a succession of passes through different roll stands of the mill.

Steel sheet piles are long structural sections with a vertical interlocking system that create a continuous wall.

The interlocks consist of a groove one of whose legs has been suitably flattened.

Steel sheet piling h pile products hammer steel inc.

The most common materials for seawalls and bulkheads are steel concrete and timber.

The piles are fully compatible with the mgf shoring product range.

A temporary application provides access and safety for construction in a confined area.

Steel sheet piling is the most widely used bulkhead material.

Sheet pile walls provide structural resistance by utilizing the full section.

Once the work is completed the sheet piling is removed.

This flattening forms the tongue which fits into the groove of the second sheet.

The walls are often used to retain either soil or water.