Strong lightweight and recoverable three dimensional ceramic nanolattices.

Strong lightweight and recoverable three dimensional ceramic nanolattices.

Strong lightweight and recoverable three dimensional ceramic nanolattices by lucas r.

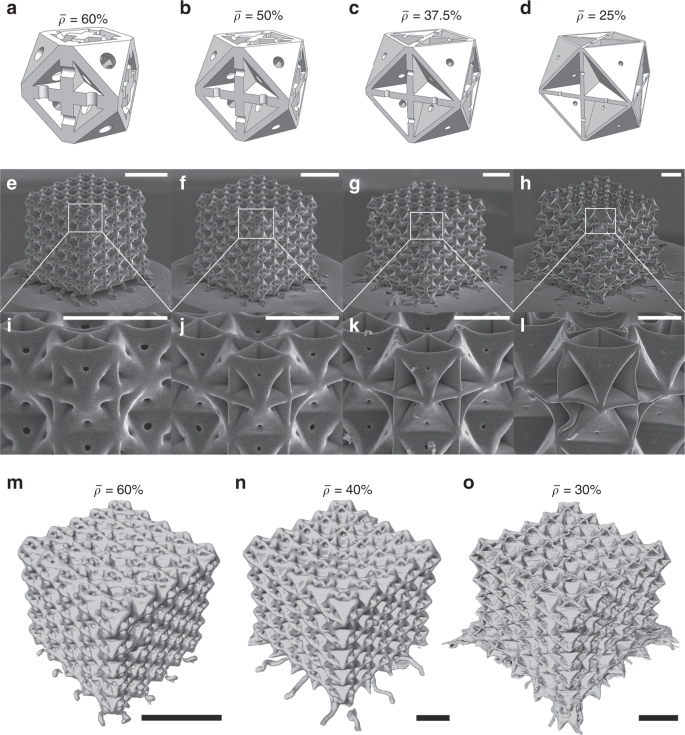

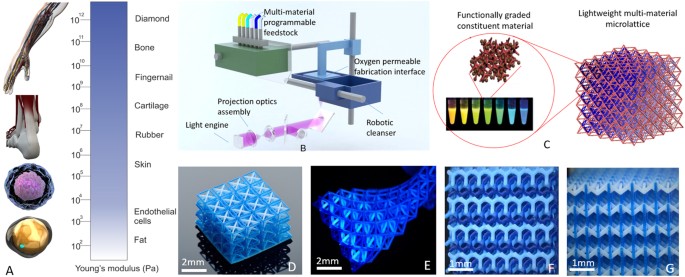

A long standing challenge in modern materials manufacturing and design has been to create porous materials that are simultaneously lightweight strong stiff and flaw tolerant.

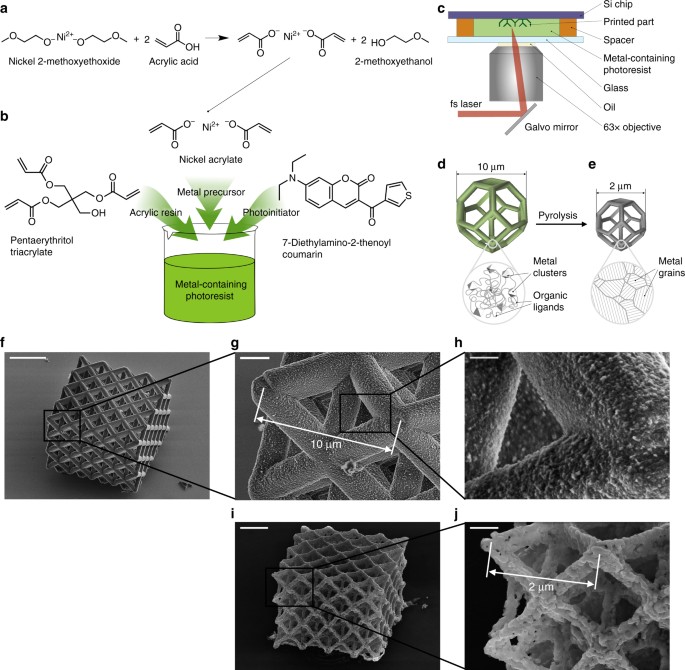

Direct laser writing and pyrolysis at high temperature.

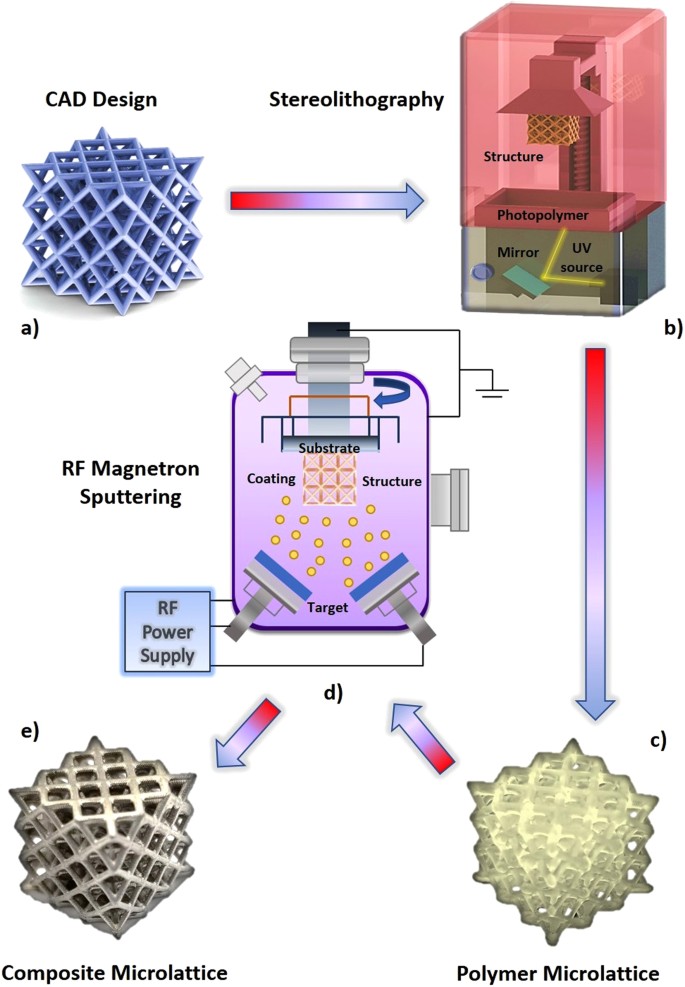

Hollow tube alumina nanolattices were fabricated using two photon lithography.

Greer1 2 ceramics have some of the highest.

Strong lightweight and recoverable three dimensional ceramic nanolattices lucas r.

Meza satyajit das julia r.

Here we fabricated pyrolytic carbon nanolattices with designable topologies by a two step procedure.

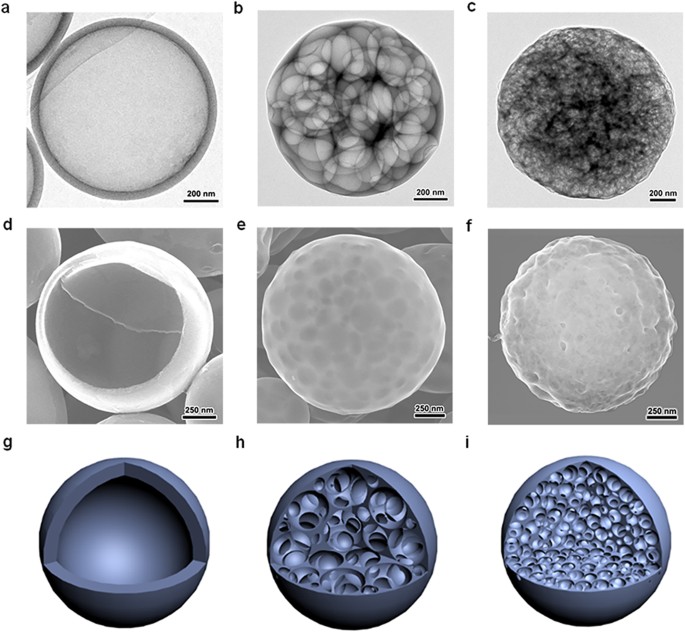

To produce nanolattice materials polymer templates are manufactured by high resolution 3d printing processes such as multiphoton lithography or by self assembly techniques.

The smallest characteristic size of the nanolattices.

Strong and energy absorbing and can recover their original shape after compressions in excess of 50 strain.

Ceramic metal or composite material nanolattices are formed by post treatment of the polymer templates with techniques including pyrolysis atomic layer deposition electroplating and electroless plating.

Greer1 2 ceramics have some of the highest strength and stiffness to weight ratios of any material but are suboptimal for use as structural materials because of their brittleness and sensitivity to flaws.

Greer science 12 sep 2014.

Strong lightweight and recoverable three dimensional ceramic nanolattices meza lucas r.

Strong lightweight and recoverable three dimensional ceramic nanolattices meza lucas r.

Hollow tube alumina nanolattices composed of nanoscale ceramic through hybrid technique including tpa atomic layer.

Meza 1satyajit das julia r.

Reports low density materials strong lightweight and recoverable three dimensional ceramic nanolattices lucas r.

Hollow tube alumina nanolattices were fabricated using two photon lithography atomic layer deposition and oxygen plasma etching.

2014 strong lightweight and recoverable three dimensional ceramic nanolattices.