All compounds are non latex kent compound click to view data sheet k2702 k7000 k2500 k3800 k4500 k2170 k8700 k4060 k8600 k2620 k2200 k9001 k3877.

Thermoplastic elastomer sheet.

Typical manufacturing techniques include.

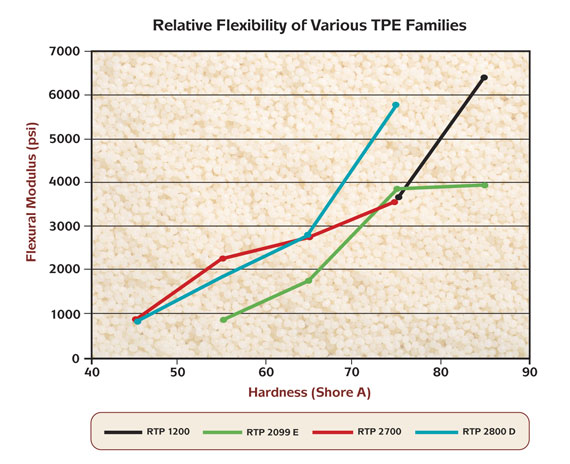

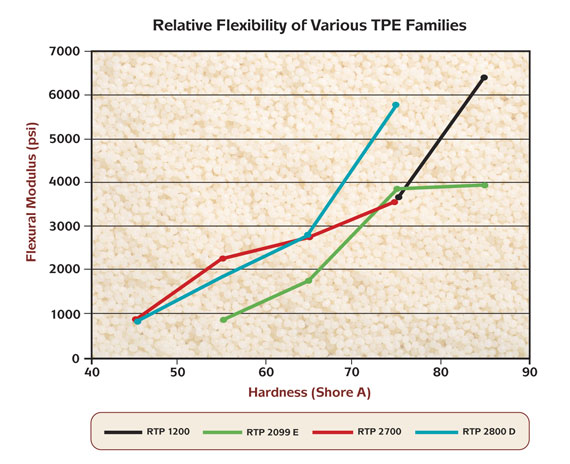

Tpe combines the desirable characteristics of vulcanized rubber such as flexibility and low compression set with the processing ease of thermoplastics.

The ability to be stretched to moderate elongations and upon the removal of stress return to something close to its.

Thermoplastic elastomer tpe sheet tpe is a diverse family of rubber like materials that can be processed and recycled like thermoplastic materials.

Tpe thermoplastic elastomer is a fatigue resistant sheet which is a combination of rubber and polypropylene.

Because of its rubber content tpe is more heat resistant requiring heating to a higher temperature than polypropylene for thermoforming.

Processable as a melt at elevated temperature absence of significant.

In order to qualify as a thermoplastic elastomer a material must have these three essential characteristics.

After forming uniform cooling is required to minimize warpage and distortion.